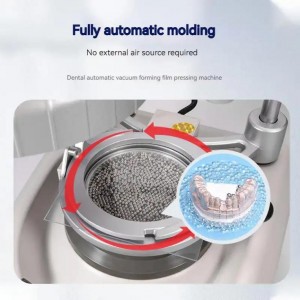

Dental pressing machine Oral intelligent full-automatic vacuum forming machine Dental braces orthodontic retainer film pressing

Dental pressing machine Oral intelligent full-automatic vacuum forming machine Dental braces orthodontic retainer film pressing

| Product name | Full-automatic vacuum forming machine |

| colour | silver |

| Performance power | 350W |

| voltage | 220V/50HZ±10%,110V/60HZ+10% |

| measure | 335*325*403mm |

| weight | 12kg |